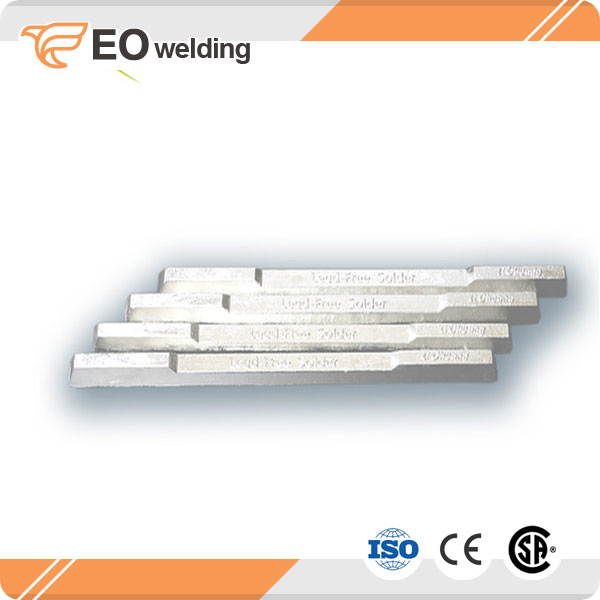

Weight: | 500g/pc |

Length: | 28.5cm |

Operating Current: | International standard |

Welding Current: | International standard |

Operating Temperature: | 245-255℃ |

Diameter: | 1.8cm*1.3cm |

Color: | Silver grey |

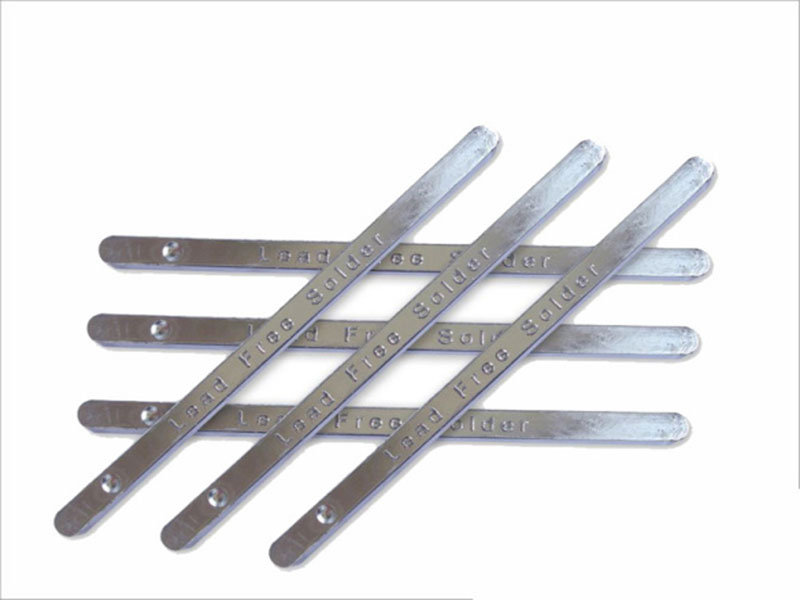

Shape: | Rectangle of bar or stick |

Melting point: | 183℃ |

Working tools: | Wave solder pot |

Dimension: | 28.5cm*1.8cm*1.3cm |

1. It has good mechanical properties and thermal fatigue resistance after soldering.

2. Silver mirrors can still appear at higher temperatures on the tin surface.

3. Long-term antioxidant

capacity and low tin slag production.

4. It has extremely good fluidity which makes the soldering process after paint stripping easier and smoother.

5. The material copper in the solder improves the reliability after

soldering.

1. Favorable Fatigue Resistance and Outstanding Soldering Performance

2.

Mid-Temperature Soldering

The manufactured product belongs to the mid-temperature solder, which is characterized by nice softness, and wonderful wetting property.

3. Benefits from Activated Rosin Flux

Active rosin flux helps improve welding performance, fast welding speed,

and excellent fluidity.

4. Ultra Strong Oxidation Resistance

Due to the addition of anti-oxidant

element, our Sn63Pb37 no-clean tin lead solder wire and solder bar can give strong resistance to oxidation. The mid-temperature solder is difficult to be softened, and its anti-oxidant capacity is greatly enhanced

Alloy Composition(%) | Dimension | Weight /piece | Melting Point(℃) | Usage | Working Point(℃) | Applications | ||

Type | Tin-Sn | Lead-Pb | ||||||

Sn63/Pb37 | 63% | 37% | 28.5*1.8*1.3cm | 500g | 183 | Wave soldering | 245-255 | LED, IT, PCB, High-class electronics, Lighting industry and Precise Instruments and other soldering |

Sn60/Pb40 | 60% | 40% | 183-190 | Wave soldering | 250-260 | |||

Sn55/Pb45 | 55% | 45% | 28.5*1.8*1.3cm | 500g | 183-203 | Dip soldering | 255-270 | Normal Electrical, Mechanical, Toys field, Lighting, Lamp holder and Socket |

Sn50/Pb50 | 50% | 50% | 183-216 | Dip soldering | 260-275 | |||

Sn45/Pb55 | 45% | 55% | 183-227 | Dip soldering | 270-300 | |||

Sn40/Pb60 | 40% | 60% | 28.5*1.8*1.3cm | 500g | 183-238 | Dip soldering | 280-310 | Battery, Cannery, Fuse, Radiators, Automobile parts and any other soldering with normal requirements |

Sn35/Pb65 | 35% | 65% | 183-247 | Dip soldering | 290-330 | |||

Sn30/Pb70 | 30% | 70% | 183-255 | Dip soldering | 295-335 | |||

Sn25/Pb75 | 25% | 75% | 183-266 | Dip soldering | 300-350 | |||

Sn20/Pb80 | 20% | 80% | 183-280 | Dip soldering | above 350 | |||

1. Reply the inquiry within 24 hours.

2. As a manufacturer, we can offer much more competitive price than trade company

3. Good quality and professional suggestion

4. Various of Composition available.

5. Provide free Samples for testing.

6. Spectrum analyzer--technical support to help customers to analyze their samples.

1. Dimension: 28.5cm*1.8cm*1.3cm, around 500grams/pc

2. Package:

25kgs/box, 2boxes/carton.

3. Dimension of box: 30.5cm*19.3cm*7cm.

4. Dimension of carton: 32cm*21cm*17cm.

5.10-20 days after receiving the deposit

All the cartons are exporting double corrugated carton, wrapped by PVC stripes to avoid damage during transportation.

1. Do you have successful transaction records?

Yes, of course. We have many times of successful transaction records which is showed on Alibaba.

2. Where are your customers come from?

We have current customers from Peru, U.A.E, Bangladesh, Cambodia, Philippines, Hongkong, Ecuador, Kenya, United Kingdom and USA. Potential customers from Ireland, Greece, Turkey, Nigeria, Thailand, Colombia, Brazil, Chile and so on.

3. Can you produce according to the samples?

A: Yes, we can produce by

your samples or technical drawings.

4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

5. Do you have repeat orders from your customers?

Yes, we have been keeping good relationships with our customers and have several repeat orders from USA, UK, Ecuador, Philippines, Cambodia, UAE, Bangladesh, Peru and Hongkong customers.