In common with the other copper-based alloys, cast brasses have excellent resistance to normal atmospheric corrosion. They gradually darken over a period of time due to a tarnish film which forms on the surface. This film is mainly oxide, but in locations where there is sulphur pollution, a proportion will be sulphide. This film eventually becomes stable and protective, and no further oxidation occurs. It is very thin and smooth and in no way interferes with the electrical function of a brass casting.

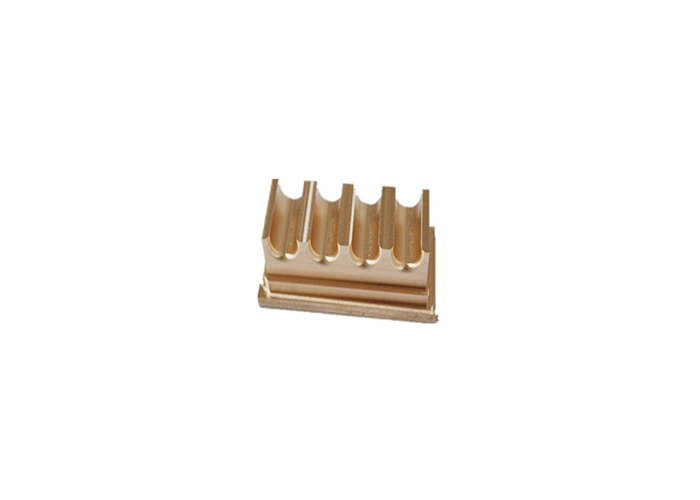

For complex shaped components where the high conductivity of copper is not required, cast brasses with good mechanical properties, good machinability and corrosion resistance provide a cost effective option for engineers.

● Electrical hardware

● Lugs

● Wiping glands

● Eye bolts

● Earthing rods

● Earth bars

● Terminal blocks

● Terminal connectors

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.