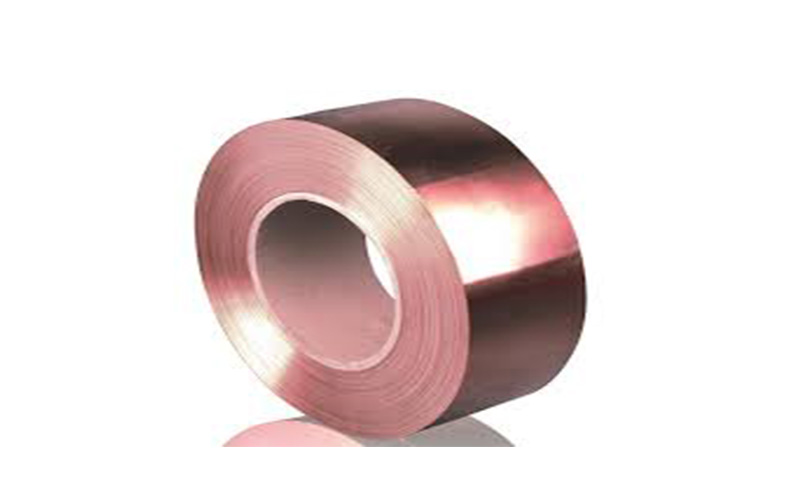

Product Name | H80 Brass Strips |

Thickness | 0.4MM |

Width | 100MM |

Material | Brass, C26000,C24000,C26800,C27000,C27200 |

Grade | Brass |

Cu (Min) | 80% |

Alloy Or Not | alloy |

Quality standard | ISO9001:2008 |

conductivity | good |

OEM | YES |

Hardness | 1/4H,1/2H,H |

Brass is a binary alloy composed of copper and zinc that has been produced for millennia and is valued for its workability, hardness, corrosion resistance and attractive appearance.

H80 Brass Strips Application:

1. Alpha Brasses: Alpha brasses contain less than 37% zinc melted into copper and are named for their formation of a homogenous (alpha) crystal structure. Such brasses are softer than their counterparts and, therefore, more easily cold worked, welded and brazed.

2. Alpha-Beta Brasses: Alpha-beta brasses contain between 37-45% zinc and are made-up of both the alpha grain structure, as well as a beta grain structure that is more similar to that of pure zinc. More common than alpha brass, alpha-beta brass is both harder and stronger and, consequently, is usually hot worked by extrusion or stamping and die-casting.

3. Beta Brasses: Although much more rarely used than alpha or alpha-beta brasses, beta brasses make-up a third group of the alloy that contain greater than 45% zinc content. Such brasses form a beta structure crystal and are harder and stronger than both alpha and alpha-beta brasses. As such, they can only be hot worked or cast.

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.

Premium Quality

Fast Delivery

Small Order Acceptable

Wonderful Teamwork

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Our application technology expert provide the best material and recommendation

One-stop service