Cupronickel (also known as copper-nickel) is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. Despite its high copper content, cupronickel is silver in colour.

Due to the specific properties of nickel and copper alloys, they are applied in various domains of industry e.g. mint industry, armaments industry, desalination industry, marine engineering, extensively used in the chemical, petrochemical and electrical industries.

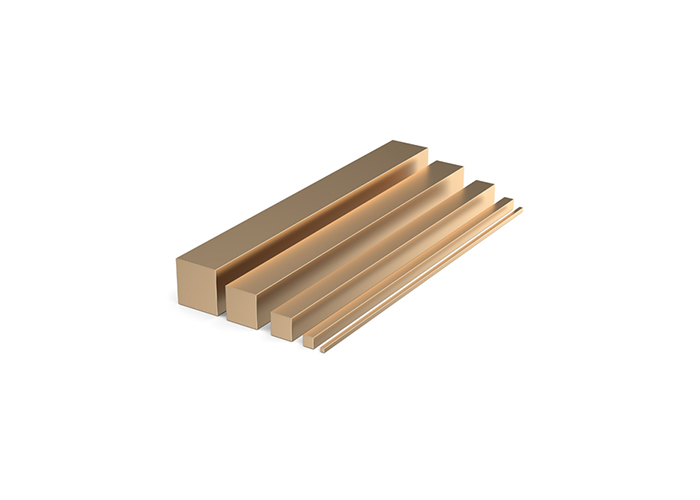

Grade Char | ||||||

China | International Standard | United States | Japan | France | United Kingdom | Germany |

BAI13-1 | MHA13-3 | |||||

Chemical Composition | |||||||||||||

Alloy | Ni+ Co | Fe | Mn | Zn | Al | Si | Mg | Pb | S | C | P | Cu | Impurities |

BAl3 -3 | 12.0- 15.0 | 1.0 | 0.50 | 2.3- 3.0 | 0.003 | 0.01 | Rest | 1.9 | |||||

BAl6 -1.5 | 5.5- 6.5 | 0.50 | 0.20 | 1.2- 1.8 | 0.003 | Rest | 1.1 | ||||||

Cupronickel is highly resistant to corrosion in seawater. For this reason, it is used for piping, heat exchangers and condensers in seawater systems, marine hardware, and sometimes for the propellers, crankshafts and hulls of premium tugboats, fishing boats and other working boats.

Another common use of cupronickel is in silver-coloured modern-circulated coins. A typical mix is 75% copper, 25% nickel, and a trace amount of manganese. In the past, true silver coins were debased with cupronickel.

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.