Round Seamless C260, C270, C272 and C330 Brass tubing is commonly used for architectural detail and industrial design elements. Alloys are comparable in strength, formability and weldability and are not heat treatable.

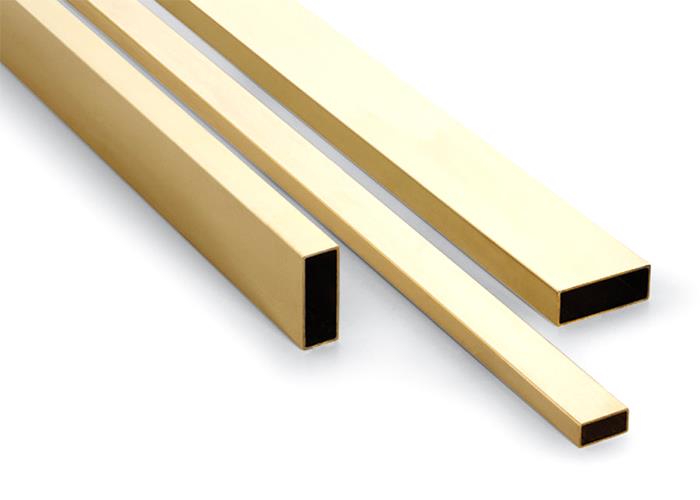

Brass C272 Square Tube is used for both architectural and structural purposes. It has very high machinability and a high resistance to corrosion. C272 is not heat treatable.

Grade Chart | |||||

China | International Standard | United States | Japan | United Kingdom | Germany |

H59 | CuZn41 | C28000 | C2800 | CZ109 | CuZn39 |

H62 | CuZn38 | C27400 | C2740 | CuZn40 | |

H65 | CuZn35 | C26800 | C2680 | CZ107 | CuZn36 |

H68 | CuZn32 | C26000 | C2600 | CuZn33 | |

H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 |

H80 | CuZn20 | C24000 | C2400 | CZ103 | CuZn20 |

H85 | CuZn15 | C23000 | C2300 | CZ102 | CuZn15 |

H90 | C22000 | C2200 | CZ101 | CuZn10 | |

H96 | CuZn4 | C21000 | C2100 | CZ125 | CuZn5 |

Chemical Composition | ||||||

Alloy | Cu | Fe | Pb | Ni | Zn | Impurities |

H59 | 57.0-60.0 | 0.3 | 0.5 | 0.5 | Rest | 1 |

H62 | 60.5-63.5 | 0.15 | 0.08 | 0.5 | Rest | 0.5 |

H65 | 63.5-68.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H68 | 67.0-70.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H70 | 68.5-71.5 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H80 | 79.0-81.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H85 | 84.0-86.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H90 | 88.0-91.0 | 0.1 | 0.03 | 0.5 | Rest | 0.2 |

H96 | 95.0-97.0 | 0.1 | 0.03 | 0.5 | Rest | 0.2 |

Mechanical Properties | |||||||||||

Alloy | Melting Temperature /℃ | Boiling Point /℃ | Density /kg·(kg·mˉ3) | Specific Heat Capacity /J·(kg·℃)ˉ1 | Linear Expansion Coefficient | Thermal Conductivity /W·(m·K)ˉ1 | Conductivity /%IACS | Conductivity /%IACS | Resistivity /μΩ·m | ||

| Liquid Temperature | Solidus Temperature |

|

|

|

|

|

| Solid State | Liquid State |

|

H59 | 896 | 886 |

| 8400 |

| 21.0X10ˉ6 | 125.1 |

|

|

| 0.0025 |

H62 | 906 | 899 |

| 8430 |

| 20.6X10ˉ6 | 116.7 | 27 | 0.071 |

| 0.0017 |

H65 | 936 | 906 |

| 8470 |

| 20.1X10ˉ6 | 116.7 | 27 | 0.067 |

|

|

H68 | 939 | 910 |

| 8500 |

| 20.0X10ˉ6 | 116.7 | 27 | 0.064 |

| 0.0015 |

H70 | 951 | 916 | 1150 | 8530 | 0.09 | 19.9X10ˉ6 | 120.9 | 28 | 0.062 | 0.39 | 0.0015 |

H75 | 981.2 |

|

| 8630 |

| 19.6X10ˉ6 | 120.9 | 30 | 0.057 |

|

|

H80 | 1001.2 | 966 | 1240 | 8660 | 0.093 | 19.1X10ˉ6 | 141.7 | 32 | 0.054 | 0.33 | 0.0015 |

H85 | 1026.3 | 991 | 1300 | 8750 | 0.095 | 18.7X10ˉ6 | 151.7 | 37 | 0.047 | 0.29 | 0.0016 |

H90 | 1046.4 | 1026.3 | 1400 | 8800 | 0.095 | 18.4X10ˉ6 | 187.6 | 44 | 0.04 | 0.27 | 0.0018 |

H96 | 1071.4 | 1056.4 | 1600 | 8850 | 0.093 | 18.0X10ˉ6 | 243.9 | 57 | 0.031 | 0.24 | 0.0027 |

These Brass Tubes are used in different areas including Furniture & Lighting Fixtures, General Engineering Purposes, and Arsenic Brass Tubes for Sugar Industries, Admiralty Brass Tubes Tubes for Evaporators & Coolers, Aluminum Brass Tube, Brass Tube for Sanitary Fittings & Accessories and Brass Tubes for Agriculture Equipment.

● Sugar factories

● Heavy engineering industry

● Power generation plants

● Heat exchangers

● Automobile industry

● Condensers

● Plumbing applications

● Hand Pumps

● Ammunition and General Engineering

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.