The higher the content of zinc in brass, its strength is higher, plasticity is slightly lower. Industrial use of brass, zinc content does not exceed 45%, high zinc content will produce brittle, the alloy performance deterioration. Commonly used alloying elements are silicon, aluminum, tin, lead, manganese, iron and nickel. Adding aluminum to brass can increase the yield strength and corrosion resistance of brass, slightly reduce the plasticity. Brass with less than 4% aluminum has good processing, casting and other comprehensive performance.

Grade Chart | |||||

China | International Standard | United States | Japan | United Kingdom | Germany |

H59 | CuZn41 | C28000 | C2800 | CZ109 | CuZn39 |

H62 | CuZn38 | C27400 | C2740 | CuZn40 | |

H65 | CuZn35 | C26800 | C2680 | CZ107 | CuZn36 |

H68 | CuZn32 | C26000 | C2600 | CuZn33 | |

H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 |

H80 | CuZn20 | C24000 | C2400 | CZ103 | CuZn20 |

H85 | CuZn15 | C23000 | C2300 | CZ102 | CuZn15 |

H90 | C22000 | C2200 | CZ101 | CuZn10 | |

H96 | CuZn4 | C21000 | C2100 | CZ125 | CuZn5 |

Chemical Composition | ||||||

Alloy | Cu | Fe | Pb | Ni | Zn | Impurities |

H59 | 57.0-60.0 | 0.3 | 0.5 | 0.5 | Rest | 1 |

H62 | 60.5-63.5 | 0.15 | 0.08 | 0.5 | Rest | 0.5 |

H65 | 63.5-68.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H68 | 67.0-70.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H70 | 68.5-71.5 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H80 | 79.0-81.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H85 | 84.0-86.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H90 | 88.0-91.0 | 0.1 | 0.03 | 0.5 | Rest | 0.2 |

H96 | 95.0-97.0 | 0.1 | 0.03 | 0.5 | Rest | 0.2 |

Mechanical Properties | |||||||||||

Alloy | Melting Temperature /℃ | Boiling Point /℃ | Density /kg·(kg·mˉ3) | Specific Heat Capacity /J·(kg·℃)ˉ1 | Linear Expansion Coefficient | Thermal Conductivity /W·(m·K)ˉ1 | Conductivity /%IACS | Conductivity /%IACS | Resistivity /μΩ·m | ||

| Liquid Temperature | Solidus Temperature |

|

|

|

|

|

| Solid State | Liquid State |

|

H59 | 896 | 886 |

| 8400 |

| 21.0X10ˉ6 | 125.1 |

|

|

| 0.0025 |

H62 | 906 | 899 |

| 8430 |

| 20.6X10ˉ6 | 116.7 | 27 | 0.071 |

| 0.0017 |

H65 | 936 | 906 |

| 8470 |

| 20.1X10ˉ6 | 116.7 | 27 | 0.067 |

|

|

H68 | 939 | 910 |

| 8500 |

| 20.0X10ˉ6 | 116.7 | 27 | 0.064 |

| 0.0015 |

H70 | 951 | 916 | 1150 | 8530 | 0.09 | 19.9X10ˉ6 | 120.9 | 28 | 0.062 | 0.39 | 0.0015 |

H75 | 981.2 |

|

| 8630 |

| 19.6X10ˉ6 | 120.9 | 30 | 0.057 |

|

|

H80 | 1001.2 | 966 | 1240 | 8660 | 0.093 | 19.1X10ˉ6 | 141.7 | 32 | 0.054 | 0.33 | 0.0015 |

H85 | 1026.3 | 991 | 1300 | 8750 | 0.095 | 18.7X10ˉ6 | 151.7 | 37 | 0.047 | 0.29 | 0.0016 |

H90 | 1046.4 | 1026.3 | 1400 | 8800 | 0.095 | 18.4X10ˉ6 | 187.6 | 44 | 0.04 | 0.27 | 0.0018 |

H96 | 1071.4 | 1056.4 | 1600 | 8850 | 0.093 | 18.0X10ˉ6 | 243.9 | 57 | 0.031 | 0.24 | 0.0027 |

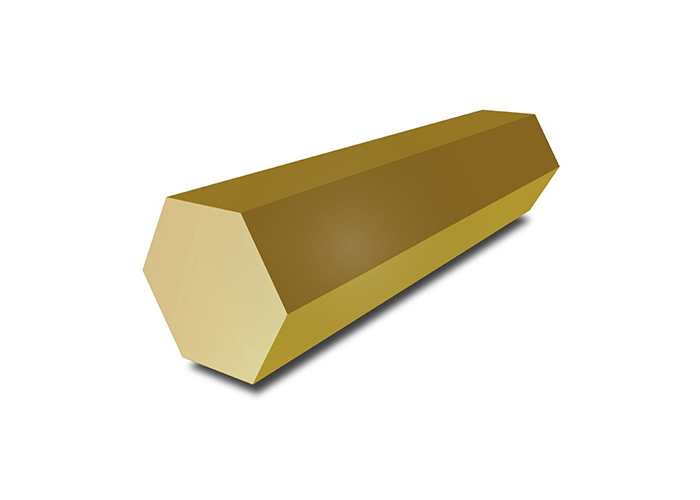

Brass Rod is made available by us in different shapes and material grades. These are of excellent quality, thus ensuring in them superior durability as well as resistivity against unfavorable work conditions. Here, our expertise also lies in making these brass rods available as per the specifications and drawings as provided by the customers. Some of the different parameters these can be delivered in include in terms of sizes, dimensions and lengths.

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.