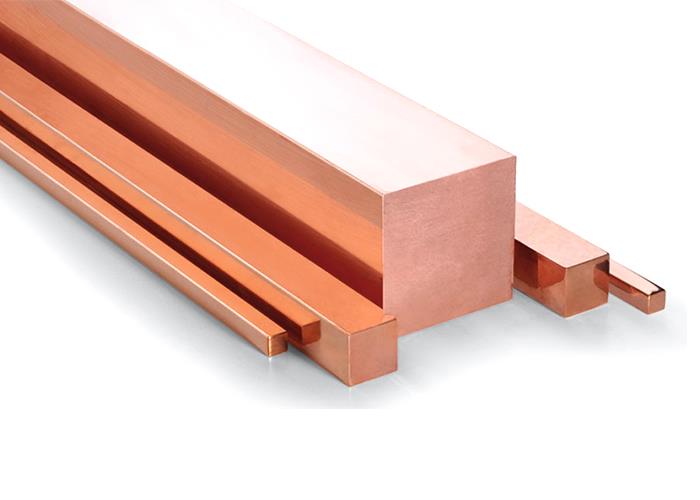

Pure Copper Bar is available in different finish options including forged, hot rolled, extruded as well as in cold worked options in dimensional finish as demanded by the customers. These precision constituted and finished Pure Copper Rod can be also made available in hard, half-hard as well as soft finish conditions in required dimensions.

Grade Chart | |||||

China | International Standard | United States | Japan | United Kingdom | Germany |

T2 | Cu-RTP | C11000 | C1100 | C101 | R-Cu57 |

TU1 | Cu-OF | C10200 | C1020 | C110 | OF-Cu |

TU2 | Cu-OF | C10300 | C1020 | C103 | OF-Cu |

TP1 | Cu-DLP | C12000 | C1201 | SW-Cu | |

TP2 | Cu-DHP | C12200 | C1220 | C106 | SF-Cu |

Chemical Composition | |||||||||||||

Alloy | Cu+ Ag | P | Ag | Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O |

T2 | 99.9 | 0.001 | 0.002 | 0.002 | 0.005 | 0.005 | 0.005 | ||||||

TU1 | 99.97 | 0.002 | 0.001 | 0.002 | 0.002 | 0.004 | 0.002 | 0.003 | 0.002 | 0.004 | 0.003 | 0.002 | |

TU2 | 99.95 | 0.002 | 0.001 | 0.002 | 0.002 | 0.004 | 0.002 | 0.004 | 0.002 | 0.004 | 0.003 | 0.03 | |

TP1 | 99.9 | 0.004-0.012 | |||||||||||

TP2 | 99.9 | 0.015-0.04 | |||||||||||

Mechanical Properties | |||||||

Alloy | State | Tensile Test | Hardness Test | ||||

Thickness/mm | Tensile | Percentage Elongation After | Thickness/mm | HV | HRB | ||

T2 | R | 0.4-14 | ≥195 | ≥30 | |||

M | 0.3-10 | ≥205 | ≥30 | ≥0.3 | ≤7 | ||

Precision engineered and finished Pure Copper Rod is available in hard, half-hard as well as in soft conditions in Extruded, Forged, Hot Rolled, as well as Cold worked options, in different dimensions. Further, our team also ensures that the copper material used making Pure Copper Rod is made available with minimum copper content of 99.99% as per IS-191.

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.