Brass Ingots are created by smelting one Tin Ingot and three Copper Ingots in an Alloy Furnace. They are not to be confused with Bronze Ingots, which are made from copper and tin dusts in a crafting grid, but serve completely different purposes. Brass Ingots, however, cannot be used in an Energy Condenser or Transmutation Tablet to create more of them like Bronze Ingots. The primary use of Brass is for crafting Pneumatic Tubes and other RedPower2 Machines. Brass is similar to Gold Ingots, but the texture is slightly darker.

Grade Chart | |||||

China | International Standard | United States | Japan | United Kingdom | Germany |

H59 | CuZn41 | C28000 | C2800 | CZ109 | CuZn39 |

H62 | CuZn38 | C27400 | C2740 | CuZn40 | |

H65 | CuZn35 | C26800 | C2680 | CZ107 | CuZn36 |

H68 | CuZn32 | C26000 | C2600 | CuZn33 | |

H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 |

H80 | CuZn20 | C24000 | C2400 | CZ103 | CuZn20 |

H85 | CuZn15 | C23000 | C2300 | CZ102 | CuZn15 |

H90 | C22000 | C2200 | CZ101 | CuZn10 | |

H96 | CuZn4 | C21000 | C2100 | CZ125 | CuZn5 |

Chemical Composition | ||||||

Alloy | Cu | Fe | Pb | Ni | Zn | Impurities |

H59 | 57.0-60.0 | 0.3 | 0.5 | 0.5 | Rest | 1 |

H62 | 60.5-63.5 | 0.15 | 0.08 | 0.5 | Rest | 0.5 |

H65 | 63.5-68.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H68 | 67.0-70.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H70 | 68.5-71.5 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H80 | 79.0-81.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H85 | 84.0-86.0 | 0.1 | 0.03 | 0.5 | Rest | 0.3 |

H90 | 88.0-91.0 | 0.1 | 0.03 | 0.5 | Rest | 0.2 |

H96 | 95.0-97.0 | 0.1 | 0.03 | 0.5 | Rest | 0.2 |

Mechanical Properties | |||||||||||

Alloy | Melting Temperature /℃ | Boiling Point /℃ | Density /kg·(kg·mˉ3) | Specific Heat Capacity /J·(kg·℃)ˉ1 | Linear Expansion Coefficient | Thermal Conductivity /W·(m·K)ˉ1 | Conductivity /%IACS | Conductivity /%IACS | Resistivity /μΩ·m | ||

Liquid Temperature | Solidus Temperature | Solid State | Liquid State | ||||||||

H59 | 896 | 886 | 8400 | 21.0X10ˉ6 | 125.1 | 0.0025 | |||||

H62 | 906 | 899 | 8430 | 20.6X10ˉ6 | 116.7 | 27 | 0.071 | 0.0017 | |||

H65 | 936 | 906 | 8470 | 20.1X10ˉ6 | 116.7 | 27 | 0.067 | ||||

H68 | 939 | 910 | 8500 | 20.0X10ˉ6 | 116.7 | 27 | 0.064 | 0.0015 | |||

H70 | 951 | 916 | 1150 | 8530 | 0.09 | 19.9X10ˉ6 | 120.9 | 28 | 0.062 | 0.39 | 0.0015 |

H75 | 981.2 | 8630 | 19.6X10ˉ6 | 120.9 | 30 | 0.057 | |||||

H80 | 1001.2 | 966 | 1240 | 8660 | 0.093 | 19.1X10ˉ6 | 141.7 | 32 | 0.054 | 0.33 | 0.0015 |

H85 | 1026.3 | 991 | 1300 | 8750 | 0.095 | 18.7X10ˉ6 | 151.7 | 37 | 0.047 | 0.29 | 0.0016 |

H90 | 1046.4 | 1026.3 | 1400 | 8800 | 0.095 | 18.4X10ˉ6 | 187.6 | 44 | 0.04 | 0.27 | 0.0018 |

H96 | 1071.4 | 1056.4 | 1600 | 8850 | 0.093 | 18.0X10ˉ6 | 243.9 | 57 | 0.031 | 0.24 | 0.0027 |

Brass is an alloy made of copper and zinc. The proportions of zinc and copper may vary to create various kinds of brasses with different properties: strength, ductility, hardness, color, antimicrobial, electrical and thermal conductivity and corrosion resistance.

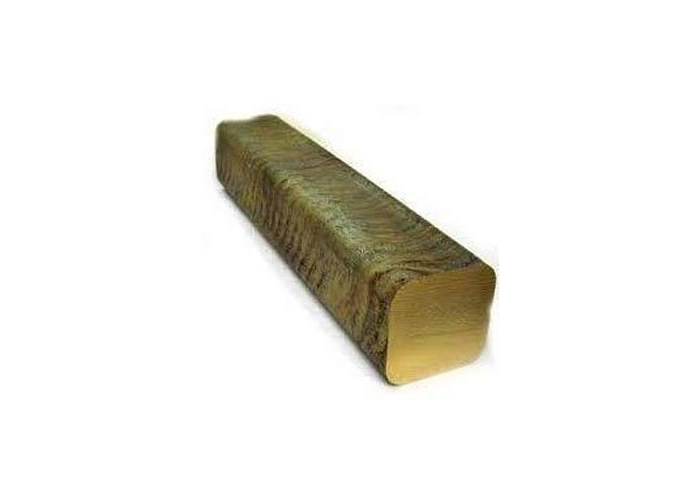

The introduction of modern production process in continuous casting allows to have a superior product on quality, compared to the traditional brass ingot, with features of constant homogeneity that guarantee a higher customer satisfaction for the purposes which is principally addressed: sanitary taps and industrial valves, fittings, handles, mechanical and artworks.

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.