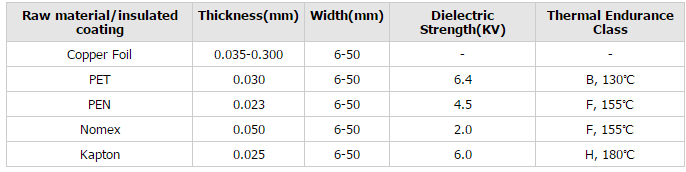

Specifications of Pre-insulated Copper Foil:

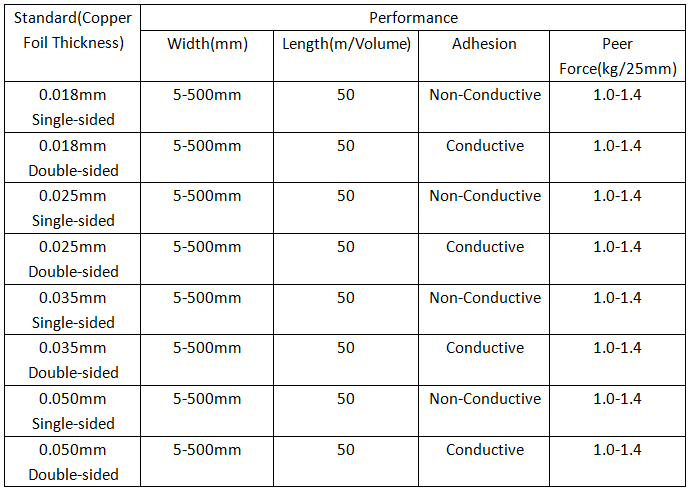

Copper foil tape can be divided into single and double conductive copper foil:

Single conductive copper foil tape refers to one side having an overlying non-conductive adhesive surface, and bare on the other side, so it can conduct electricity; so it is said that it is single-sided conductive copper foil.

Double-sided conductive copper foil refers to copper foil that also has an adhesive coating, but this adhesive coating is also conductive, so it is called double-sided conductive copper foil.

1) Standard: Regard of different insulated coating material, the thermal endurance class are B, F, H in according to RoHS-2002/95/EC

2) Delivery State: With 100 and 200m copper foil round on the inner diameter of 76mm coil core

3) Storage Condition: No more than 6 months, under the dry and cool environment condition about 20℃

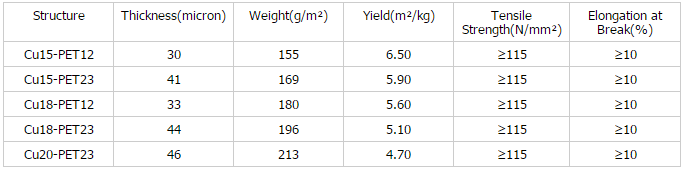

4) Technical Properties:

Available on pads and spool

Characteristics of Copper Foil:

Notes:

1) Can be used below 100°C

2) Elongation is at about 5%, but can be changed in accordance with customer specifications.

3) Should be stored in a room temperature and can be stored for less than one year.

4) When in use, keep adhesive side clean of unwanted particles, and avoid repeated use.

Advantages:

1) Copper foil purity is higher than 99.95%

2) The function is to eliminate electromagnetic interference (EMI)

3) Electrostatic charge will be grounded, strongly bonded, good conductive propertied.

4) Reduces the necessary cross section of copper because of optimal shape in comparison to round wires

5) Ease of getting admittance for a winding construction due to the optimal safety

6) More reliable due to reduction of vibration, better thermal conductivity

7) Prevents danger of short circuit between primary and secondary windings

Pre-insulated Copper Foil Performance:

One side is copper, other side has insulating paper; In the middle is an imported pressure-sensitibe acrylic adhesive. Copper foil had strong adhesion and elongation.

It is mainly due to copper foil’s excellent electrical properties that during processing it can have a good conductive effect. Secondly we use adhesive coated nickel to shield electromagnetic interference on the surface of copper foil.

Pre-insulated Copper Foil Application:

1) Various types of transformers

2) Mobile phones

3) Computers

4) PDA, PDP, LCD monitors

5) Coaxial cables

6) Signal cables

7) Control cables

8) Instrumentation cables

9) LAN cables

10) Data communication cables

11) Notebook computers, printers and other domestic consumer products

EO Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) EO Metal Standard

2) Customization

Premium Quality

Fast Delivery

Small Order Acceptable

Wonderful Teamwork

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Our application technology expert provide the best material and recommendation

One-stop service