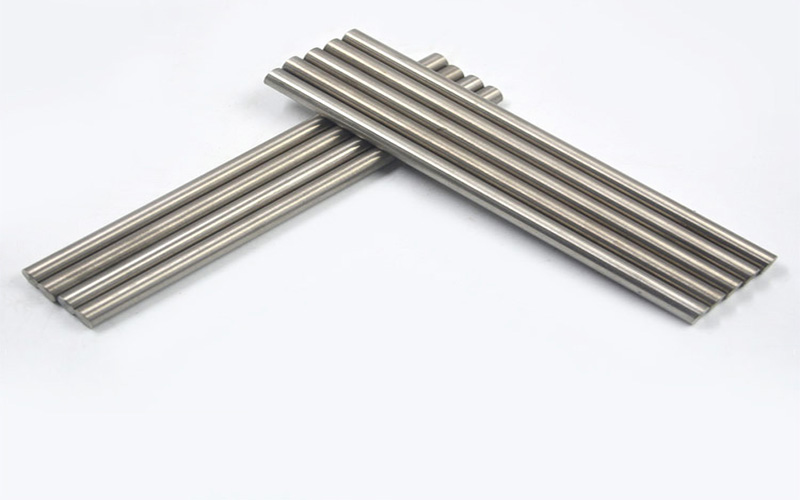

Product Name | Casting Manganese Bronze bar |

Diameter | 3mm~800mm |

Shape | Round |

Length | Clients` Requirement |

Grade | C86400 |

Alloy Or Not | Alloy |

Al (Min) | 56% |

Physical Properties

Melting Point - Liquidus°F | 2156 |

Melting Point - Solidus°F | 2084 |

Densitylb/cu in. at 68°F | 0.32 |

Specific Gravity | 8.86 |

Electrical Conductivity% IACS at 68°F | 4 |

Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F | 14.7 |

Coefficient of Thermal Expansion 68-57210-6 per °F (68 – 572°F) | 9.7 |

Specific Heat CapacityBtu/ lb /°F at 68°F | 0.09 |

Modulus of Elasticity in Tensionksi | 19000 |

Chemical Composition

Element | ||||||||

Cu(1,2) | Pb | Sn | Zn | Fe | Ni(3) | Al | Mn | |

(1) Cu + Sum of Named Elements 99.0% min.(2) In determining Cu min., Cu may be calculated as Cu + Ni.(3) Ni value includes Co. | ||||||||

Min (%) | 56 | 0.5 | 0.5 | 34 | 0.4 | 0.5 | 0.1 | |

Max (%) | 62 | 1.5 | 1.5 | 42 | 2 | 1 | 1.5 | 1.5 |

Casting Manganese Bronze bar Application:

Form | Sub-Form | System | Standard | Description |

As Centrifugal Cast | Castings | ASTM | B271/B271M | COPPER BASE ALLOY CENTRIFUGAL CASTINGS |

As Continuous Cast | Castings | ASTM | B505/B505M | COPPER BASE ALLOY CONTINUOUS CASTINGS |

As Sand Cast | Castings | ASTM | B584 | COPPER ALLOY SAND CASTINGS FOR GENERAL APPLICATIONS |

Castings | ASTM | B763/B763M | COPPER ALLOY SAND CASTINGS FOR VALVE APPLICATIONS | |

Ingot | ||||

ASTM | B30 | COPPER BASE ALLOYS IN INGOT FORM | ||

Valves | MILITARY | MIL-V-18436 | VALVES, CHECK, BRONZE |

Packaging:

Inner: Seaworthy exporting standard packing for each piece

Outer: carton or wooden case

Or: custom made

Deliver Time: 10-15 days after receive the advanced deposit payment

Premium Quality

Fast Delivery

Small Order Acceptable

Wonderful Teamwork

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Our application technology expert provide the best material and recommendation

One-stop service